Customized controls systems

Daxner Automation yields returns: reduced need for staff, more economic production, stable product quality and improved competitiveness.

Daxner‘s modular, efficient and reliable systems for production planning, controls, regulations and surveillance include:

- Plant administration: Manages the entire production processes centrally, captures and records the current system status.

- Modular design: According to the individual requirements of any production process, different modules for raw material reception & inventory control, transport, dosing, mixing, commissioning of small ingredients, packaging etc. can be added to our core module manager arbitrarily.

- User-friendliness: All modules are constantly refined and improved based on our customers’ experience. By reducing the required input operations to an absolute minimum and by integrating additional functions according to our customers’ requirements a maximum user-friendliness is achieved.

- Full traceability: The entire material flow is constantly traced, recorded and comfortably visualized. All relevant latest standards (like EU regulation 178/2002) are met.

Advantages

Modular design

Easy configuration

Arbitrarily extendable

Interface to ERP systems

HACCP implementation

Complete traceability

Barcode operation

Multi-lingual operation

Contamination matrix

Remote maintenance

Service hotline

Visualization

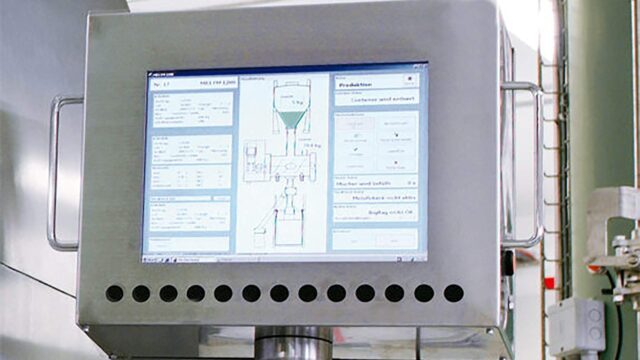

Intuitive operator terminals and process visualization yield optimized user friendliness and product transparency. Simultaneously, the reaction time of error messages are minimized by a faster operator recognition of plant state depicted graphically.

Operator terminals (touch screen) and visualization are customized, can be configured and extended arbitrarily at any point in time.

Advantages

Customized user interface

Powerful and clear process visualization

Simply, unmistakable operator terminals

Interface and administration in local language

Optional dust explosion rated design (ATEX)

Arbitrarily extendable

Controls of individual components

Individual controls systems of stand-alone components featuring “plug & play” design, emphasizing on simplest possible handling and flexibility by easy controller configuration. Interfaces to ERP system, for instance for bag filling and weighing equipment can be implemented conveniently.

Independently controlled plant components can be operated “stand-alone” or connected to existing ERP systems via a TCP-IP interface. All operator-terminals are easy to configure – recipes or programs can be re-configured without changing the controller programming itself.